The rubber industry is constantly seeking ways to optimize production processes and improve product quality. One crucial aspect of rubber manufacturing is the efficient screening of rubber powder, which directly impacts the final product's consistency and performance. Traditional screening methods often fall short, leading to inefficiencies and inconsistencies. Enter the Gaofu Tumbler Screen, a game-changer in rubber powder screening technology.

The Challenges of Rubber Powder Screening

Rubber powder, a key ingredient in various rubber products, presents unique challenges during the screening process. Its irregular particle shapes, varying sizes, and tendency to clump make it difficult to achieve consistent and efficient separation using conventional screening methods. These challenges often result in:

- Low Screening Efficiency: Traditional screens struggle to handle the irregular shapes and sizes of rubber powder, leading to incomplete separation and material loss.

- Frequent Screen Blockages: The sticky nature of rubber powder causes particles to adhere to the screen mesh, resulting in frequent blockages and downtime for cleaning.

- Inconsistent Product Quality: Inefficient screening leads to variations in particle size distribution, negatively impacting the final product's quality and performance.

Gaofu Tumbler Screen: The Solution

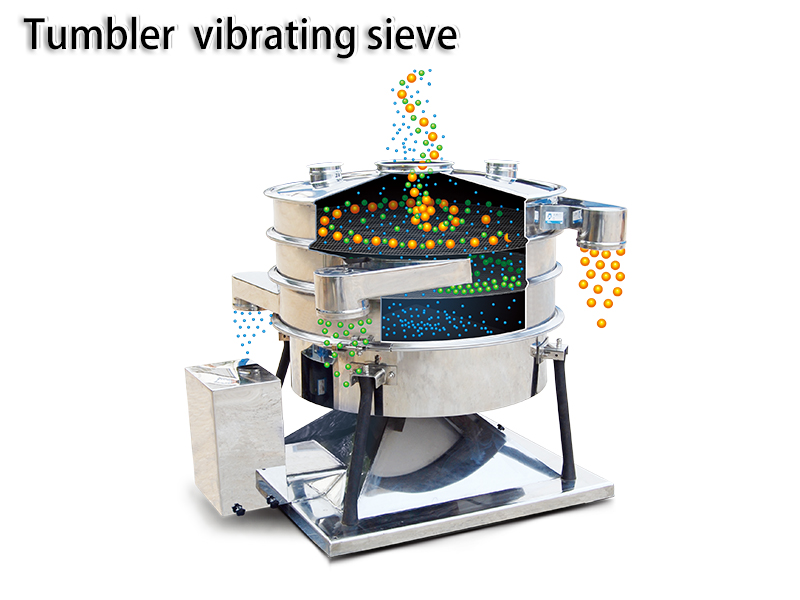

The Gaofu Tumbler Screen addresses these challenges head-on with its innovative design and advanced technology. This screening machine utilizes a unique three-dimensional rotary motion that effectively separates rubber powder particles based on size, ensuring optimal screening efficiency and product quality.

Key Features and Benefits:

- High Screening Efficiency: The tumbler screen's unique motion ensures thorough separation of rubber powder particles, maximizing yield and minimizing material loss.

- Self-Cleaning Design: The screen's continuous tumbling action prevents material buildup and blockages, ensuring uninterrupted operation and reduced maintenance.

- Gentle Handling of Material: The tumbler screen's gentle tumbling motion minimizes friction and heat generation, preserving the integrity of the rubber powder particles.

- Adjustable Screening Parameters: The screen's speed, amplitude, and angle can be easily adjusted to optimize the screening process for different rubber powder types and desired particle sizes.

- Durable and Reliable Construction: Built with high-quality materials and precision engineering, the Gaofu Tumbler Screen ensures long-lasting performance and reliability.

Applications in the Rubber Industry

The Gaofu Tumbler Screen finds widespread application in various stages of rubber manufacturing, including:

- Recycled Rubber Processing: Efficiently separating rubber powder from contaminants and achieving desired particle sizes for reuse in new rubber products.

- Tire Manufacturing: Ensuring consistent particle size distribution of rubber powder used in tire compounds, leading to improved tire performance and durability.

- Rubber Product Manufacturing: Providing high-quality, precisely screened rubber powder for various rubber products, such as seals, gaskets, and hoses.