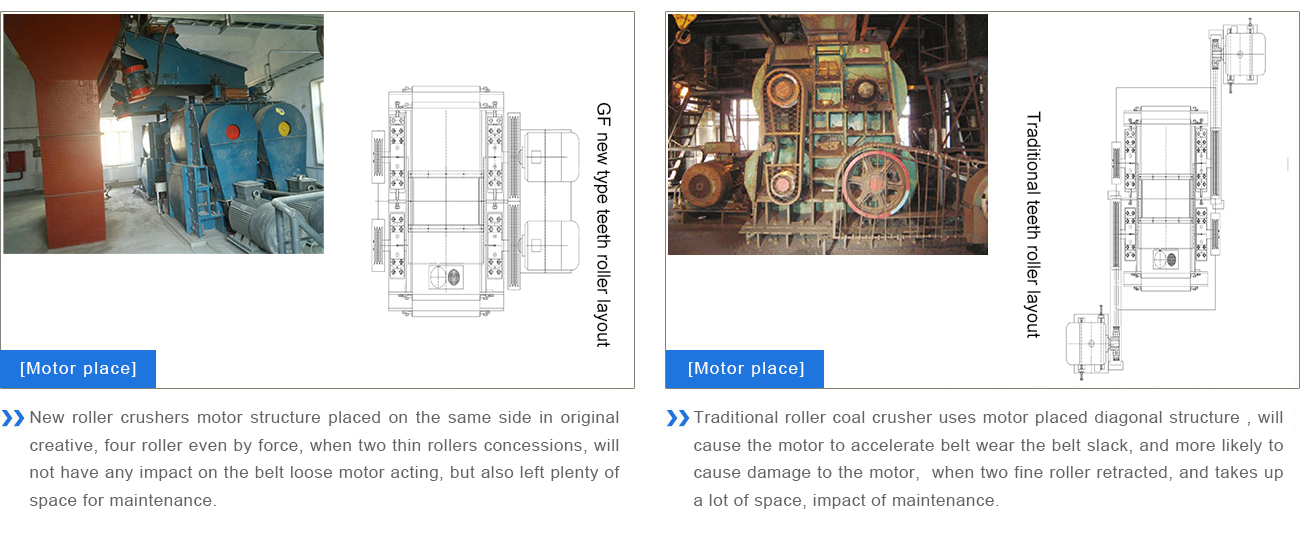

|

High Yield Screening

|

Crushing Rate Low, Grain Size Fine

|

|

| Relative roller differential speed operation with mutual scraping action, because of its higher running speed, and also has role of "former pulling back pressure, former blowing back inhaling", the crusher has no requirement of moisture and mud content in any time, will not affect the crushing effect. Material is always all into the whole out to ensure overfill force. | Crushing rate low, grain size fine: adopting combined crushing but not impact and strike breaking, it will not produce secondary crushing phenomenon, so crushing rate very low. Two teeth roller center distance will not change once fixed, the materials will be hard crushed instantly, almost no repeat broken, to ensure uniform granule. | |

|

Low Investment Costs

|

Simple Structure With Less Maintenance

|

|

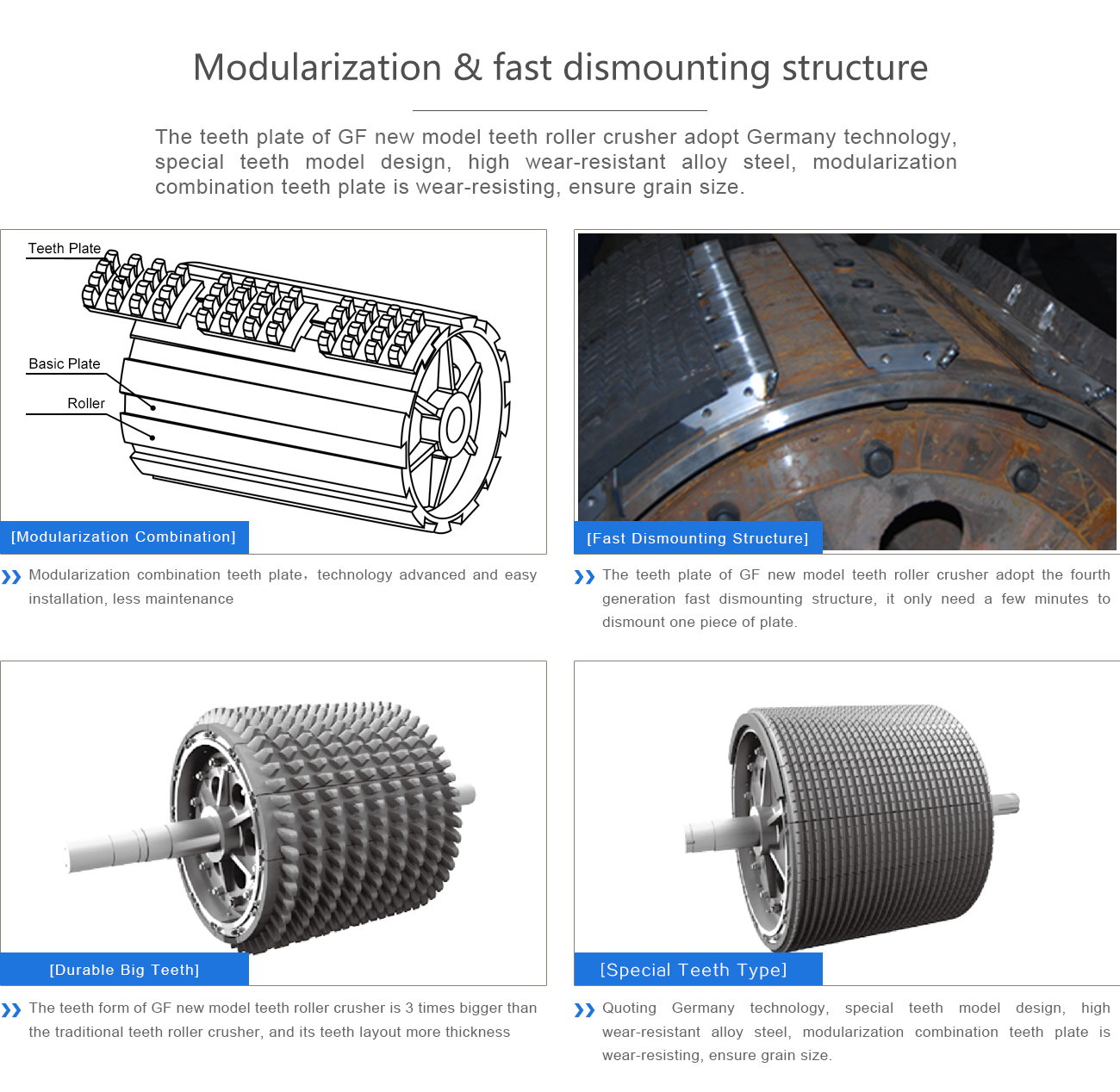

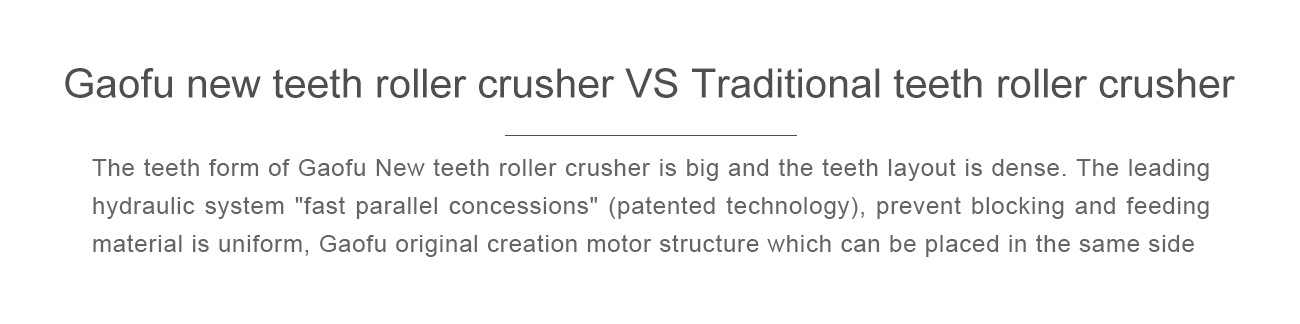

| Screen and crush together, a small investment: two teeth roller relative rotation form rotary space lattice sieve. To achieve the double effect of crushing and screening, one machine can complete the crushing and screening work. So, you don’t need to match the screening equipment, simplifying system, reduce investment cost. | Handwheel or hydraulic structure can adjust the discharging granularity quickly.The equipment adopt modular architecture, can be divided remote installation according to the site requirement, or customer can choose assembly installation, so as to lift and maintain conveniently. Standard modular composite teeth plate more interchangeability and versatility, greatly reduce the replacement cycle of the teeth plate and operating costs. | |

|

Environmental Protection & Energy Saving

|

Integrated Liquid Spring Balance Flashback Protection

|

|

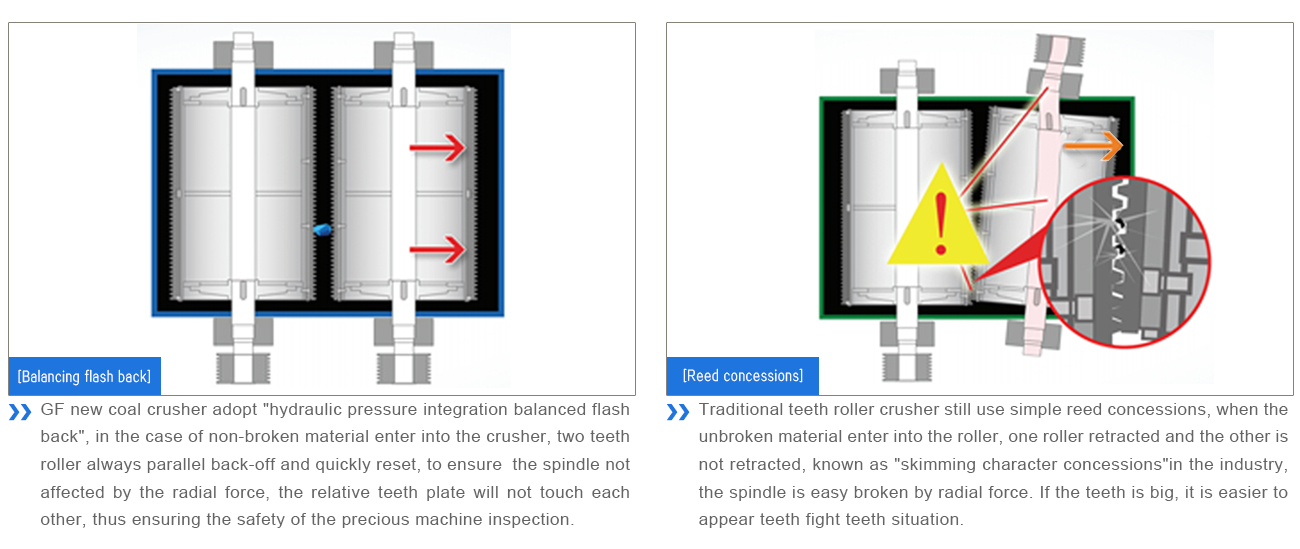

| Input size≤350mm, the outlet between 3-50 mm can be freely adjusted, a crushing ratio can reach 50.GF crusher machine energy consumption has a function of reserve and kinetic energy release.Less than 0.03mm amplitude and below 70 decibels noise, the micro positive pressure and all enclosed structure forms, completely eliminate the work-site "three evils" phenomenon, prevent workers silicosis, it is truly environmentally friendly products. | My company develops automatic concession crusher patented product for the current condition that the coal source is not fixed and more debris . When the wood and other non-magnetic alloy or rubber and other flexible objects can not be broken in the crusher, the two roller quickly and automatically retreat parallel to the above materials, and then quickly returned to the original gap position, to keep continuous operation. | |

|

Safe & Intelligent Reliability

|

Uniform Feeding & Long Service Life

|

|

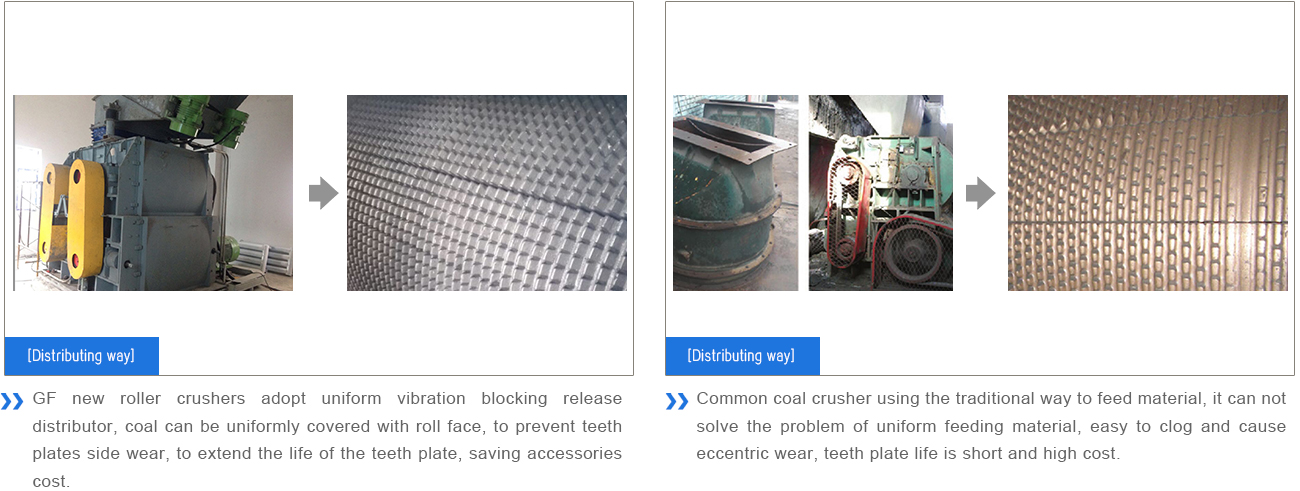

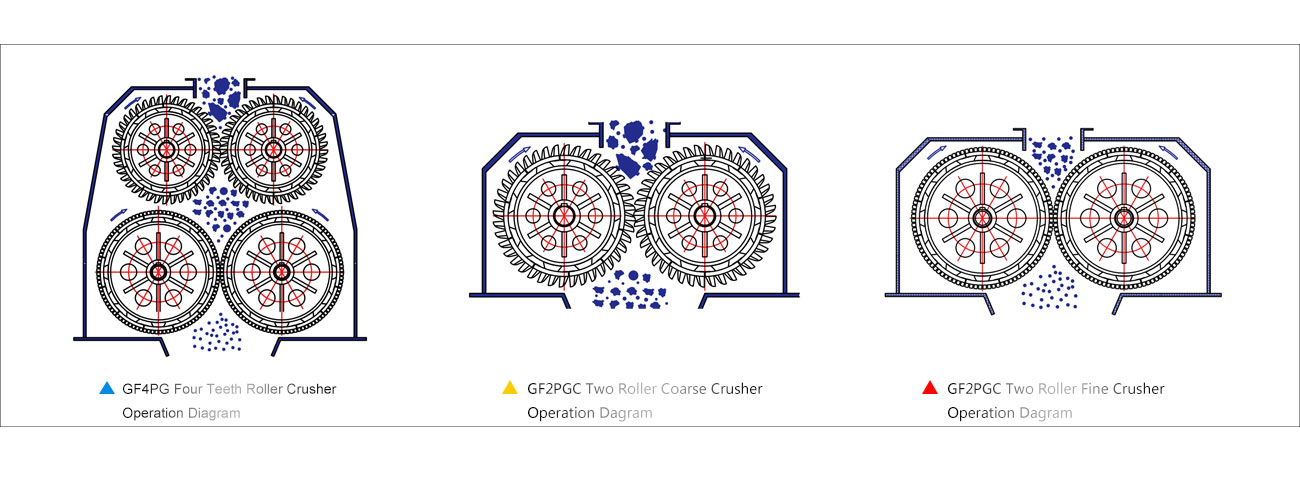

| GF2PGC Two roller coarse crusher is security smart and reliable: the machine adopts the double protection of the electrical and mechanical, cabinet is equipped with PLC programmable controller, which has the interlock protection function, can achieve local control and centralized control room manual / automatic control. It is a ideal crusher for the heating and powering. | Vibration feeding, uniform distribution: choosing our company's new type anti-adhesion and anti-blocking vibration uniform feeder, reduce the tooth plate eccentric wear, prolong the life of the tooth plate |

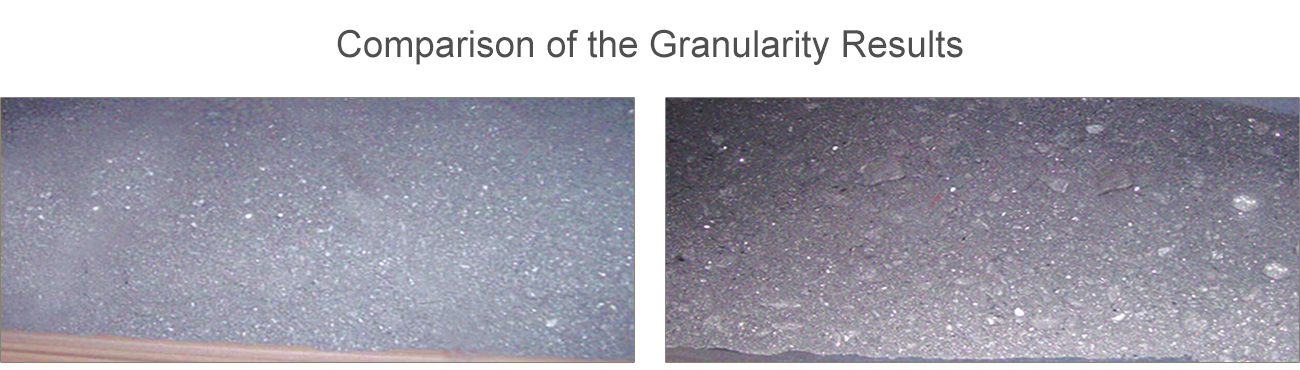

| Teeth roller coal crusher principle is: the fuel enter from up, and discharge directly from bottom outlet, without secondary crushing. To achieve the crushing purpose through crushing and screening by snap action between teeth, the grain evenly, over powder rate is very low, and its broken particle size can be quickly adjusted by the screw, to fully meet the requirements of coal-fired fluidized bed boiler, to avoid fly ash waste. 100% size guaranteed! | Hammer crusher, due to repeatedly hammering the fuel, the over crushed situation is more serious, finest material without adequate fuel will fly out, resulting in a tremendous resources waste. If calculate according to waste two thousandths per day, 700 tons of fuel was wasted a year, the direct economic loss will up to $ 800,000. |

| GF new teeth roller crushers is differential operation between two rollers, it can clean up material between two rollers, so as to prevent clogging phenomenon,100% non-stick non blocked! | Hammer crusher has mandatory requirements for fuel moisture, if the moisture more than 6%, the teeth plate will be clog, then the capacity will be lower, if the moisture reached about 10%, the production capacity will be reduced to 1/3 of the rated capacity. |

| Teeth roller crusher is a slight negative pressure operation mode, no noise, no dust spills, 100% environmental health. | Hammer crusher’s working principle, resulting in a positive pressure airflow, severe dust pollution; its mechanical vibration can cause serious noise pollution; direct harm to staff’s physical and mental health. |

The performance analysis and comparison between teeth roller crusher and hammer crusher(250t/h coal crushing as a case)

| Performance | GF teeth roller crusher | Hammer crusher | Comparative analysis | |

| Operational capability | Discharging size | Screw control can be adjusted | Need to replace the plate, mesh size is restricted | Roller convenient adjustment, fully meet the needs of granularity |

| Over crushed | Instant stealth broken, almost no re-break | Process of crushing, repeated hammering | Hammer crusher over crushed serious, low thermal efficiency of the boiler | |

| Sticky & blocking phenomenon | Relative scraping, no blocked and stick | Sticky, blocking serious (water content> 6%) | Hammer crusher easy to clogging, need to clean manually | |

| Rated output | Full rated output (any water content) | 60% of the rated output (wet and dry when unevenness) | Hammer crusher output only 35% when the water ≥10%, low efficiency | |

| Material Requirements | Suitable hardness | Low, medium and high brittle materials | Middle and high brittle materials | Low brittle materials is also effective |

| Feed size | ≤350mm | ≤160mm | A wide size range | |

| Moisture | Water content without any requirements | Request moisture content ≤6% | If excessive water, the hammer crusher easy to clogging, does not work | |

| Facilities | Vibrating screen | No need | Minimum model 1530 vibrating screen (about 13000dollars) | An additional layer to place vibrating screen in hammer crusher building |

| Heating equipment | No need | It’s need heating equipment when moisture is 6% or higher | Material not drying, hammer crusher can not working | |

| Environmental pollution | Noise (no-load operation) | Less than 70 db | More than 100 db | Hammer crusher with big noise, serious noise pollution |

| Dust

|

Roller balanced rotation, small stream, almost no dust | Hammer operation, to generate strong positive airflow, large dust | Teeth roller crusher environmental protection, no dust | |

| Vibration | Relatively balanced operation, micro-vibration | Hammer eccentric high-speed operation, big vibration | Hammer coal crusher has high requirements for infrastructure | |

| Coking | Material size in line with the requirements of the boiler operation, it does not occur due to the deposition of coke | Hammer Crusher is a flexible connection, for coal 5-20mm small stones can not be broken, small stones into the cold slag deposition on the bottom, so that the local flow of quality deterioration, severe coking | Coke can cause maintenance and safety hazards | |

| Maintenance cycle | Wearing parts replacement cycle (eight-hour day) | Teeth plate ≥6 months | Hammer, back plate, grate 2-4 months | Teeth Roller Crushers long maintenance intervals and reduced maintenance frequency, high efficiency |

| Equipment energy consumption | Equipment weight | 28.1t | 15t | Hammer crusher manufacture simple, low cost, teeth roller crusher manufacture cost is relatively high |

| Motor power(250t/h) | Four roller type total power is 180kw | (260+320)KW(Coarse broken+ fine broken) | Hammer crusher will take more 400kw power consumption per hour, according to work 10 hours a day, 300 days working plant electricity costs 0.4 yuan / kWh per annum, the annual power consumption more than 1.2 million kw, that is 480,000 yuan | |

In conclusion:

1. Teeth roller Crusher can save electricity 480,000 yuan than the hammer crusher each year(In Case of 250TlH crusher).

2. Hammer crusher needs to increase: dust collector, vibrating screen, heater, broken building civil engineering and other costs bigger than RMB 300,000.

3. Hammer crusher presence of noise, dust, coke and other environmental problems, which bring inconvenience for normal operation, bring hidden dangers for the health of employees.

4. Because the hammer crusher structure principle cause the material too easy to smash, bringing uncertainty to the circulating fluidized bed boiler for its normal working.

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

Weihai Thermal Power

Coal gangue

Weihai Heat and Power Group Co., Ltd. is a large state-owned company which integrates heating, power generation, real estate development, etc. In May 2012, Shandong Weihai Heat and Power Group publicly bid for coal crushing equipment. At that time, as many as 12 suppliers participated in the bidding and 4 major types of coal shredding equipment, our Gaofu machinery also participated in the competitive bidding war. After Shandong Weihai thermoelectric bidding group ...

Luxi Group

lump coal

Luxi Chemical Group Limited by Share Ltd is a state-owned large chemical enterprise group. It is a comprehensive chemical industry enterprise integrating chemical fertilizer, chemical and chemical equipment and installation. It is one of the largest chemical industry enterprises in the country. Because it is a large chemical enterprise, it is very strict with the safety of the equipment. The equipment is very careful and careful. After the early exploration and use of the ...

United Laboratories

Coal

Federation Pharmaceutical (Inner Mongolia) Co., Ltd. is part of Federal International Holdings Limited (Hong Kong Stock Exchange 3933), founded in April 2007, is the largest federal pharmaceutical investment, the most complete industrial chain production base, The current size of the machine is 5 × 260t/h high temperature and high pressure circulating fluidized bed boiler. In 2011, two sets of GF4PG350 and GFBTS350 were ordered for high gear roller crusher and GaoFu ...

Lee & Man Paper Manufacturing

Coal

As one of the world's leading producers of board paper and pulp, we are committed to fulfilling our social responsibilities, particularly in the area of environmental protection. In order to reduce the environmental pollution caused by papermaking sludge, Liwen papermaking adopts the method of mixing coal and burning paper sludge to treat the sludge. When wet sludge is mixed into coal, dry coal becomes wet coal with high viscosity. ...

Nanhai Jieneng

Coal

Foshan Nanhai Cannon Investment holding Co., Ltd is located under the west woodcutter mountain and the west river in the famous "4A" scenic spot of the country. After decades of development, it has become a power generation, heating, water supply and sewage treatment. Coal water slurry preparation industry-based comprehensive enterprises. Its subordinate enterprise Nanhai Jieneng fuel Co., Ltd., the original use of the 200-ring hammer crusher. ...

Shanxi Lanhua Sci-tech Venture Co., Ltd.

Coal

Shanxi Orchid Technology Venture Co., Ltd. (A Ticker:600123)is the first coal listed company in Shanxi Province and the only listed company in Jincheng. It has developed from a single coal enterprise to a coal production company, focusing on coal and chemical fertilizers. Fine coal chemical industry and other diversified industries in one of the modern enterprises, chemical fertilizer raw materials coal base in the country is one of the large enterprises. ...

GF2PGC Two Roller Coarse Crusher Parameters(Input size≤250mm, output size≤50mm.)

| Model | Capacity(t/h) | Motor model | Power(KW) | Dimensions(L*W*H) | Weight(Kg) |

| GF2PGC-120 | 100-140 | Y2-200L2-6 | 22×2=44 | 4300×1630×1000 | 8050 |

| GF2PGC-160 | 150-180 | Y2-225M-6 | 30×2=60 | 4300×1830×1000 | 9250 |

| GF2PGC-200 | 180-200 | Y2-250M-6 | 37×2=74 | 4300×2130×1000 | 10500 |

| GF2PGC-230 | 200-250 | Y2-280S-6 | 45×2=90 | 4500×1970×1200 | 12500 |

| GF2PGC-250 | 220-270 | Y2-280S-6 | 45×2=90 | 4500×2480×1200 | 13250 |

| GF2PGC-300 | 260-320 | Y2-280M-6 | 55×2=110 | 4500×2480×1200 | 14050 |

| GF2PGC-370 | 320-390 | Y2-315S-6 | 75×2=150 | 4500×2790×1200 | 16150 |

| GF2PGC-450 | 380-460 | Y2-315S-6 | 75×2=150 | 4550×3090×1200 | 18250 |

| GF2PGC-500 | 450-520 | Y2-315M-6 | 90×2=180 | 4550×3290×1200 | 20350 |

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

E-mail: gaoful@zhendongshai.com