|

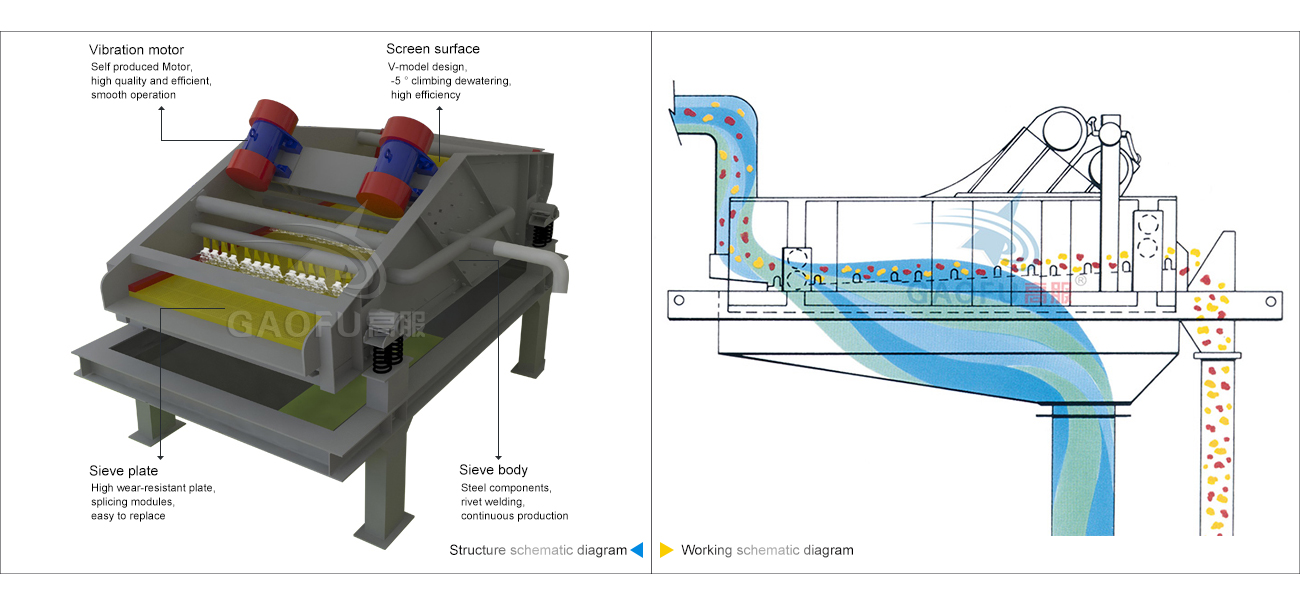

Waterproof Motor

|

Low Cost Investment

|

Continuous Dewatering Operation

|

||

| Waterproof proper frequency dedicated motor, double motor-driven self-synchronization technology , to achieve efficient of dewatering. | Compared with the traditional process, the Gaofu company new-type dry-line dewatering process has the advantages of small investment, simple process and small area, which is convenient for the system process layout. | Professional design of the frequency, amplitude, low-power source for a variety of dewatering needs 24-hour continuous operation. | ||

|

Large Capacity

|

Long Service Life

|

High Strength & Durable Structure

|

||

| V-screen design, -5゜ screen surface slope dewatering, dewatering screen with low water, high efficiency, large capacity per unit area. | High wear-resistant screen plate long life, modular assembly design, easy replacement, cost savings, screen mesh size can be selected according to requirements. | Rigid-welded steel components assembly, constitute the machine body with no internal stress, high strength, light and durable. |

Dewatering screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

Dewatering screen, also known as high-frequency dewatering screen, changing the water surface tension of pulp through the exciting force, pulp water through the screen to become the undersize material, and fine material is blocked by the screen to form the filter layer by the vibration of the forward movement of discharge. Dewatering screen is mainly used for detailings dewatering in the mineral processing industry, coal slurry dehydration of coal preparation plant, washed quartz sand dewatering and ceramic slurry dehydration, and wet and dry classification, dehydration, removal and mud removal of medium and fine granular materials in industrial sectors such as electric power, sugar making and salt making.

Tailings dry row

Iron tailings, gold tailings, copper tailings, vanadium tailings, lead and zinc tailings, graphite tailings and so on

Gaofu machinery is made for each tailings dry process technology are efficient and energy-efficient minimum operating costs of the process. Drying of the slag after filling the pit, field, dam, manufacturing building materials, the filtrate to achieve the requirements of recycling ...

Washed sand

Quartz sand, zircon sand, glass sand, building sand, foundry sand, building materials sand, potassium feldspar dehydration

Washing sand dewater screen install a special sprinkler system, the feed for multi-channel spray washing, so that the soil from the sand completely separated to ensure the smoothness of sand. The sand washing system can effectively reduce the amount of fine sand loss, so that it is controlled within 5% -10% ...

Potash feldspar dehydration

Potash feldspar

Gaofu potash feldspar dewatering screen has less investment and energy consumption than filter press, which is convenient in operation and has a better effect than spiral classifier. It is the first choice of potash feldspar mineral separation and dehydration. Potash feldspar need to be graded after milling. The large particles back to the ball milling, ...

Sludge dewatering system

Urban sewage, industrial wastewater, river sludge, wastewater treatment,

mud treatment, construction mud, drilling mud treatment

Sludge dewatering system includes slurry pump、dewater screen、 Cyclone and power supply system. Single set of systems can achieve grading、 leaching、dehydration,it can effectively reduce investment costs、operating costs. ...

| Model | Angle(°) | Mesh Size(mm) | Input Capacity(t/h) | Power(kw) | Exciter Model | Total Weight(t) |

| GFVD1036 | -5~-3 | 0.3~0.6 | 10~35 | 2 ×1.1 | 2×YZO-20-4 | 3.8 |

| GFVD1236 | -5~-3 | 18~65 | 2 ×2.4 | 2×YZO-30-4 | 4.5 | |

| GFVD1536 | -5~-3 | 30~90 | 2 ×3.1 | 2×YZO-40-6 | 5.7 | |

| GFVD1838 | -5~-3 | 40~120 | 2 ×7.5 | 4×39-6 | 6.6 | |

| GFVD2138 | -3~0 | 60~150 | 2 ×7.5 | 4×45-6 | 8.2 | |

| GFVD2538 | -3~0 | 80~200 | 2 ×11 | 4×64-6 | 11 |

Tailings dry row

Washed sand

Potash feldspar dehydration

Sludge dewatering system

Fine sand recycling machine

coal slurry dewatering

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

E-mail: gaoful@zhendongshai.com