|

Multi-level Classification

|

Cost-effective

|

High Output

|

||

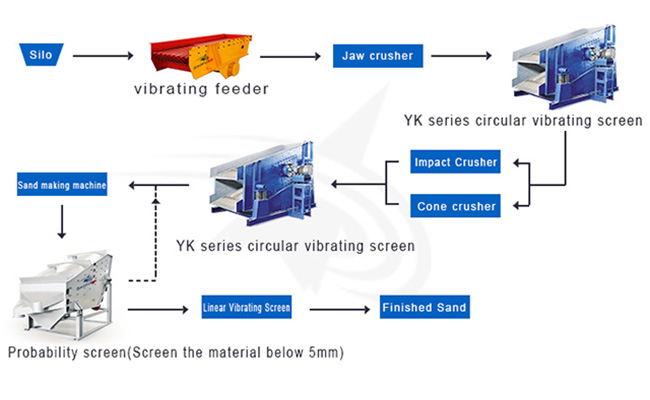

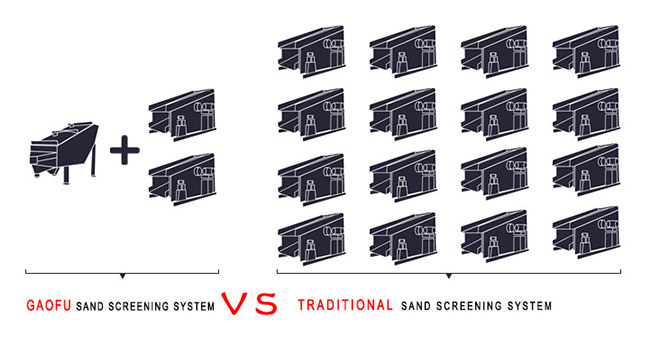

| Multi-level classification for mechanism sand or natural sand, screening mesh: 5mm ~ 2.36mm ~ 1.2mm ~ 0.6mm, some of the special mortar has been screened to 0.3mm ~ 0.15mm ~ 0.075mm. | Introduced advanced technology from Germany and Spain, etc, continuous R & D and site validation, the probability screen successfully replace the expensive imported equipment in the dry mortar production line. | probability screen capacity can reach more than 80 tons per hour, one set probability screen capacity equal multiple sets ordinary vibrating sieve, layout is easier in site . | ||

|

Longer Life Expectancy

|

Unique Structure

|

Green Environmental Protection

|

||

| Screen surface design is curved state, the external ratchet tension can easily control the screen surface tension without loose, to make the screen mesh with longer life. | Closed multi-layer design, up to five layers can be designed, and change the mesh faster, the back of the machine and the front of the discharge port are all detachable design, you can quickly replace each layer of mesh. | GLS Probability Screen Equipment Cover designed with dust removal device, it can be easily connected to the site dust removal equipment to achieve dust-free screening requirements. |

|

Multi-level classification for mechanism sand or natural sand, screening mesh: 5mm ~ 2.36mm ~ 1.2mm ~ 0.6mm, some of the special mortar has been screened to 0.3mm ~ 0.15mm ~ 0.075mm. |

|

|

GLS probability screen can reach more than 80 tons per hour |

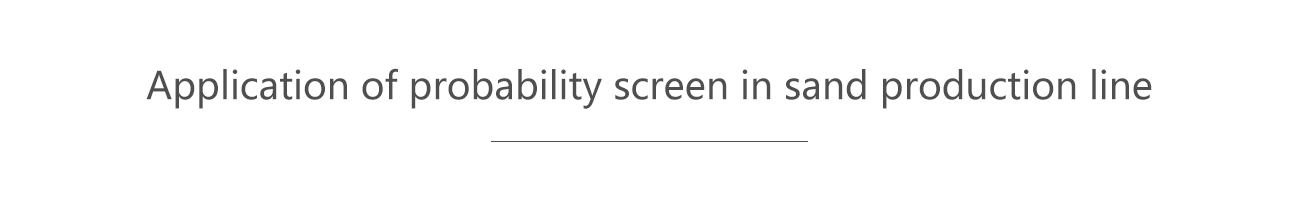

Probability screen is a kind of sieve machinery which can make use of the principle of probabilistic screening. The sieve theory points out that, the stranded time of each object in its interior is opposite to its weight in the work. Through the actual experiment, particle size is much smaller than the hole diameter, it can quickly pass the screen surface, the more close to the hole diameter, the longer the stranded time, if the diameter of the two sides are close, the stranded time of the material is the longest, popular speaking, large particles stay time is long , small particles stay time is short.

When the sieve machine starts, the symmetrical arrangement of two identical models and specifications of the vibration motor or exciter for synchronous reverse operation, the excitation force through the transmission body – motor or exciter base pass to the entire vibration body – sieve box, the sieve box drives the sieve surface to do periodic vibration, so that material in the sieve surface with the screen for directional leaping movement, meanwhile, the material less than the sieve aperture through the sieve hole fall to the bottom, as undersize material, the material larger than the sieve aperture is discharged from the outlet after the continuous jumping movement, and finally the screening operation is completed.

| Model | Layer | Screen Structure | Mesh Size(mm) | Area(㎡) | Angle(°) | Material Size(mm) | Motor Model | Power(kw) | Frequency(1/min) | Amplitude(mm) | Capacity(t/h) | Screening Efficiency |

| GLS0615 | 2-5 | Woven mesh | ~50 | 0.9n | 15-30 | ≤50 | YZO8-6 | 0.55×2 | 960 | 5-8mm | 15-50 | ≥95% |

| GLS0820 | 1.6n | YZO10-6 | 0.75×2 | 15-50 | ||||||||

| GLS1018 | 1.8n | YZO16-6 | 1.1×2 | 30-100 | ||||||||

| GLS1020 | 2.0n | YZO16-6 | 1.1×2 | 30-100 | ||||||||

| GLS1225 | 3.0n | YZO20-6 | 1.5×2 | 30-120 | ||||||||

| GLS1530 | 4.5n | YZO40-6 | 3.0×2 | 30-160 | ||||||||

| GLS1536 | 5.4n | YZO50-6 | 3.7×2 | 30-160 | ||||||||

| GLS1830 | 5.4n | YZO50-6 | 3.7×2 | 30-180 | ||||||||

| GLS1836 | 6.5n | YZO50-6 | 3.7×2 | 30-180 | ||||||||

| GLS2030 | 6.0n | YZO50-6 | 3.7×2 | 30-180 | ||||||||

| GLS2040 | 8.0n | YZO50-6 | 3.7×2 | 50-200 |

Note: The column “n” of screen surface area(㎡)show layer,for example, 0.9n meaning 0.9㎡×n.

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

E-mail: gaoful@zhendongshai.com