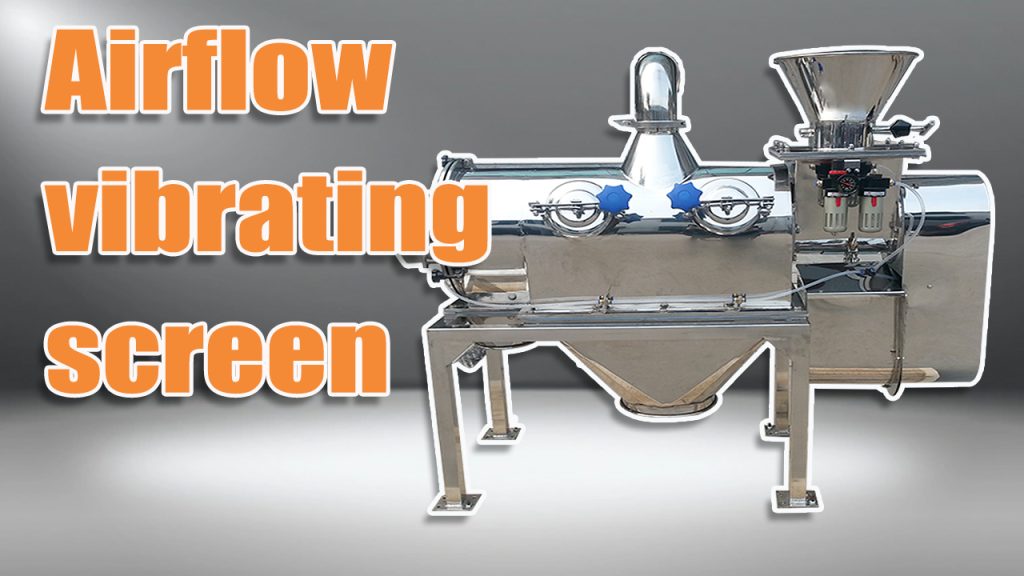

In modern industrial applications, particularly in the production and processing of pigment powders, the quality and consistency of the final product are heavily dependent on the effectiveness of the sieving process. One of the most efficient tools for this task is the airflow vibrating screen, a specialized piece of equipment designed to remove impurities and ensure that only particles with the desired size make it through to the next stage of production.

Purpose of Sieving: Purity and Particle Size Control

When it comes to pigment powder, precise particle size is crucial—not only for achieving uniform color distribution but also for ensuring smooth texture, enhanced dispersion, and optimal performance in end-use applications such as paints, coatings, plastics, and inks. The primary goal of the sieving process using an airflow vibrating screen is decontamination and particle size classification—removing oversized particles and unwanted debris while retaining only pigment particles that meet strict granulometric specifications.

Key Advantages of the Airflow Vibrating Screen

What makes the airflow vibrating screen particularly suited for this task is a combination of its versatility, reliability, and specialized functional design. Some of the major benefits include:

1. Flexible Configuration: Standalone or Integrated Operation

The airflow vibrating screen can be used as a standalone unit or in multi-machine setups, depending on the scale of production and the complexity of the sieving requirements. This flexibility makes it suitable for both small-scale laboratories and large industrial manufacturing lines.

2. Integration into Air Pressure Systems

Designed with modern processing systems in mind, the airflow vibrating screen can be seamlessly integrated into positive or negative pressure air circuits, allowing it to become part of a fully enclosed, dust-free production environment. This not only enhances product safety but also ensures compliance with environmental and occupational health standards.

3. Continuous and Stable Operation

Unlike conventional sieving equipment that may require frequent stops and maintenance, the airflow vibrating screen is built for long-duration continuous operation. Its robust structure and stable performance ensure minimal downtime, reducing production interruptions and improving overall process efficiency.

4. Safety and Reliability

Safety is a paramount concern in any production environment. The airflow vibrating screen is engineered for safe and reliable operation, with mechanisms in place to prevent mechanical failure, contamination, or exposure to hazardous dust during operation.

5. De-agglomeration of Pseudo-Caking Materials

Pigment powders often exhibit a phenomenon known as pseudo-caking, where particles form soft, temporary clumps due to moisture, electrostatic charges, or storage conditions. The airflow vibrating screen is uniquely capable of re-dispersing these agglomerated particles, ensuring that they are properly sieved and do not compromise the quality of the final product.