In the fields of building materials, cement, brick manufacturing, and mining, shale is a common raw material that requires precise and energy-efficient size reduction before it can be further processed. However, due to its layered structure and variable hardness, crushing shale efficiently while maintaining particle quality poses a significant challenge.

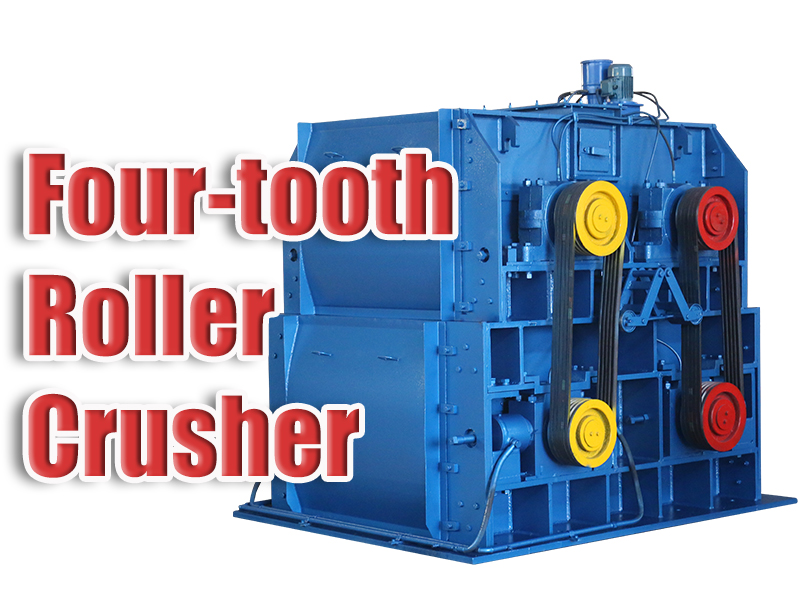

Enter the four-tooth roll crusher—a cutting-edge solution designed to tackle shale with unmatched crushing performance, intelligent operation, and energy efficiency. This equipment is rapidly becoming a preferred choice in modern shale processing lines, thanks to its ability to handle large feed sizes, minimize over-crushing, and deliver uniform output with minimal environmental impact.

Built for Shale: Smart and Stable Crushing

The four-tooth roll crusher is designed for stable, intelligent, and reliable operation, even in the demanding conditions of shale crushing. Unlike conventional crushers that often experience uneven force distribution or blockages, this system utilizes precisely engineered four-tooth rollers and a robust mechanical structure that ensures a smooth and consistent crushing process.

The equipment's automation-friendly controls and hydraulic systems also allow operators to manage load conditions in real-time, further enhancing stability and reducing manual intervention.

Double Crushing Efficiency with Composite Fracture Technology

What truly sets this crusher apart is its composite crushing mechanism, which delivers a rapid, high-impact “hard break” to the material. When shale enters the crushing chamber, it is instantly fractured through coordinated shear and compression, leading to extremely efficient particle size reduction in a single crushing cycle.

This technology not only doubles the crushing efficiency compared to traditional crushers but also reduces the need for secondary or tertiary crushing, helping operators save on energy and maintenance costs.

Low Over-Crushing Rate and Excellent Particle Control

Over-crushing is a common problem when processing brittle materials like shale, resulting in excessive fines and dust that waste material and degrade product quality. The four-tooth roll crusher is engineered to minimize over-crushing, thanks to its optimized tooth design and controlled feed-to-roll distance.

The result is a high-quality, uniformly sized output, with adjustable discharge settings that can deliver particles ≤10mm, tailored to meet the precise requirements of downstream processes such as sintering, molding, or combustion.

Versatile Input and Adjustable Output: High Crushing Ratio

One of the defining features of this equipment is its wide feed and fine discharge range. Capable of handling input sizes up to 300mm, it delivers adjustable output sizes down to ≤10mm, making it versatile enough for a range of shale applications.

With a crushing ratio of up to 50:1 in a single pass, this machine significantly reduces the number of crushing stages needed, thereby simplifying the processing line and improving plant efficiency.

Eco-Friendly and Energy Efficient

Environmental performance is increasingly critical in today’s industrial landscape. The four-tooth roll crusher stands out not only for its mechanical performance but also for its low energy consumption and minimal dust emissions.

Its intelligent design reduces idle time and power waste, while its enclosed crushing system and minimal vibration contribute to a cleaner, safer, and quieter work environment. It’s an ideal solution for enterprises committed to green manufacturing and sustainable development.

Key Advantages at a Glance

- Stable and Intelligent Operation: Hydraulic automation and precision control ensure smooth, reliable performance.

- High Crushing Efficiency: Composite breaking technology delivers instant fracture, doubling output rates.

- Low Over-Crushing Rate: Uniform particles with minimal fines improve product quality and yield.

- Large Feed Capacity and Adjustable Output: Handles materials up to 300mm with discharge sizes ≤10mm.

- Environmentally Friendly and Energy-Saving: Reduced power consumption and dust emissions for a greener operation.

- One-Step High-Ratio Crushing: Achieves crushing ratios of up to 50:1 in a single pass.