White carbon black (precipitated silica) is a widely used industrial material, valued for its high surface area, porosity, and reinforcing properties. It plays a crucial role in industries such as rubber manufacturing, coatings, plastics, and pharmaceuticals. However, due to its lightweight, fine particle size, and tendency to agglomerate, traditional screening methods often fail to provide the required precision in particle size distribution.

To address this challenge, the airflow vibrating screen has emerged as a highly effective solution. This advanced screening technology ensures that white carbon black is precisely classified, improving product quality and process efficiency.

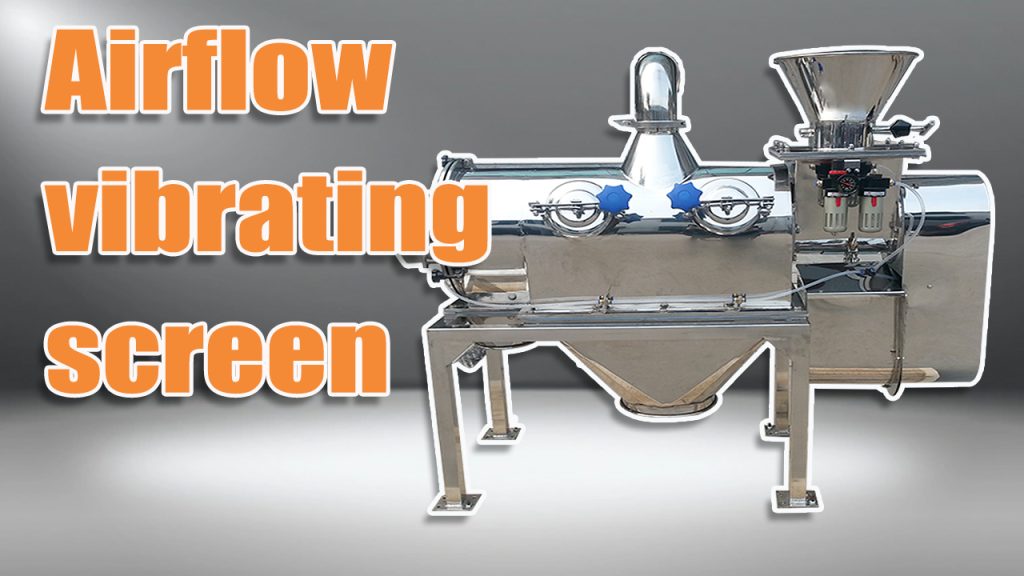

How the Airflow Vibrating Screen Works

The airflow vibrating screen is a unique screening system that combines vibratory motion with an airflow mechanism, making it especially suitable for ultrafine and lightweight powders like white carbon black. The screening process involves:

- Airflow Acceleration: A powerful airflow system disperses the material, preventing clumping and allowing fine particles to flow freely.

- Vibratory Screening: The vibrating mechanism ensures that only particles within the desired size range pass through the mesh, while oversized particles are effectively separated.

- Precision Classification: The combination of vibration and airflow achieves highly accurate particle size distribution, ensuring that the final product meets strict industry standards.

Advantages of Using an Airflow Vibrating Screen for White Carbon Black

- Highly Precise Screening – Ensures that the white carbon black is classified into uniform particle sizes, improving product consistency.

- Prevents Blockage & Agglomeration – The airflow system reduces powder sticking and agglomeration, which is a common issue with fine silica materials.

- High Efficiency & Speed – Compared to traditional vibrating screens, the airflow vibrating screen provides faster throughput and higher separation efficiency.

- Improved Product Quality – The precise classification enhances the performance of white carbon black in downstream applications, such as in rubber reinforcement and coatings.

- Reduced Material Waste – By optimizing the separation process, manufacturers can minimize waste and maximize the usable yield of high-quality white carbon black.