The production of Chinese medicine formula particles is based on the decocting requirements of traditional Chinese medicine decoctions. The production process rules are respectively formulated according to different kinds. The basic process routes are: the optimization of raw materials of Chinese traditional medicine, processing, extraction, concentration, drying, fine powder screening, pelletize, finished granules screening, packaging.

Chinese medicine particles are generally boiling drying or granulated, it will have the phenomenon of inconsistencies in the size of the powder and granulation in the granulation process, the waste of labor costs and the loss of waste particles landing, in resulting the loss of corporate profits, consumer complaints, etc. , Business owners have a headache, in order to solve the problems encountered by customers, Gaofu supply one-stop solution for you.

All raw materials’ quality for the production of formula particles are good, the optimization of Chinese medicine raw material is essential, Chinese medicine raw material net, pick, remove impurities through a linear vibrating sieve, to ensure the quality of Chinese medicine raw materials: recommend SZF-A linear vibrating sieve

After drying, remove some agglomeration or additional ingredients of the large particles through 80 mesh, the the material will enter into the silo to do the granulation. Recommend S49-A rotary vibrating sieve, WSA centrifugal sifter

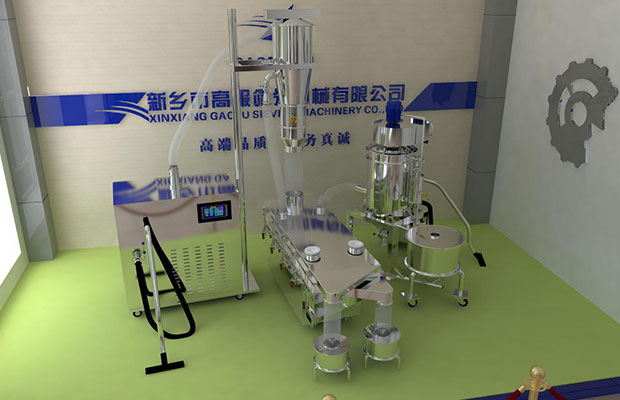

After granulation, the upper install 16 mesh screen, the lower install 30, 40 mesh screen (according to manufacturers’ different requirement), the material of up and down enter into the pelletmill to do granulation again through the vacuum, the middle qualified products into the silo Packaging. Recommended equipment GFZX pellet sieve!

For the finished product, the granules are more fragile and easy to be broken again, and the light weight of the powder and poor liquidity. Gaofu design the GFZX granule pill sieve: the upper, middle and lower three layers are made with different inclination angles; the upper layer removes the false agglomeration and reduces the repeated processes; middle layer is finished product scroll forward with suitable speed, both to ensure the capacity and material not broken. The bottom is fine powder, quickly discharged and then make granulation, no waste.

For the pharmaceutical industry, both the device cleanliness and the regular demolition and disinfection requirements, we have been humane improvement of these devices, more conducive to the operation of workers. In addition, the device can be configured to feed silos and dust removal equipment to improve work efficiency and reduce environmental risks.

|

|

1. Free dust feeding station solve the flying powder in the manual transit material, resulting in direct waste, dust environment also have a direct impact on the health of workers, a device to solve two major problems.

2. Particulate linear vibrating sieve: According to the characteristics of the particles: Pseudo agglomeration, the finished product is relatively brittle and easily crushed again, the powder is light and poor fluidity. We design: the upper, middle and lower three layers are made with different inclination angles; the upper layer removes the false agglomeration and reduces the repeated processes; middle layer is finished product scroll forward with suitable speed, both to ensure the capacity and material not broken. The bottom is fine powder, quickly discharged and then make granulation, no waste.

3. Cleaning dust collector: Automatic vacuum dust mop, instead of artificial traditional cleaning, it will filter the collected floor material automatically and solve the dust generated in the screening, so that the entire process without dust, no waste, the material with same particles.

Chongqing Taiji Industry (Group) Co.,Ltd.

Chinese medicine particles

The granules were screened by hand sieve, the efficiency was low and the production capacity did not match.After that, the screening equipment was also purchased through the middleman, because he did not understand the screening process, the model selection did not match, resulting in the screening accuracy ...

Beijing Tongrentang

Chinese medicine powder

Beijing tongrentang is a century-old Chinese shop, which is the pride of all Chinese."Although the processing of the complex will not be able to save labor, the taste is not dare to reduce the material power", tong ren tang's strict requirements on the purchase and production, achieve its century-old shop. ...

Chinese Herbal Medicine

Active Pharmaceutical Ingredient(API)

Chinese medicine pill

Chinese medicine formula particles

Chinese medicine powder

Medicine

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

E-mail: gaoful@zhendongshai.com