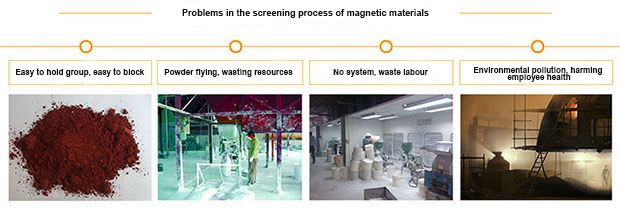

The accuracy and fineness of magnetic particles are important factors that affect the performance of magnetic composites, and also determine its market value. Therefore, the screening process is the most important part in the production of magnetic powder, but due to the high hardness and strong viscosity of the magnetic material, , Easy to hold the group and easy to fly and other characteristics, resulting in the screening process of magnetic conglutinate, blocking net phenomenon is more serious, while using the traditional screening process dust flying dust, environmental pollution, the loss of raw materials and other issues has also been a magnetic material production big trouble. North Mine Magnet engineers have also been through many experiments, use vibrating screen, ultrasonic sieve or the use of wind and similar air flow sieve equipment, but for rough screening, screening is difficult to carry out effectively, not only low yield, excessive grain size , But also dust flying, serious pollution.

|

|

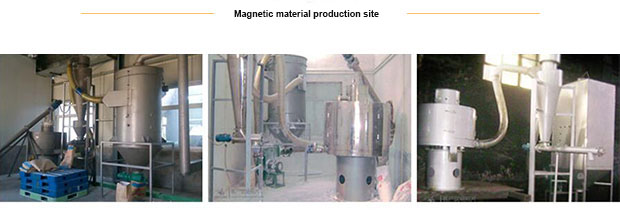

Gaofu company for the characteristics of magnetic materials, research and development and production of magnetic materials dedicated screening machine system. Because of the magnetic material dedicated screen use vertical mesh, air atomization spray over the network technology, Solve the magnetic material sticky, easy to block mesh screening problems; the entire screening system using negative pressure cycle design, with additional dust and other equipment, that is, to solve the dust and pollution problems, put an end to the waste of raw materials, to achieve the environment Clean and bumper economic value.

WS series air flow screening machine adopts vertical net loading mode. The material enters into the screen machine through the feed inlet. Using the air as the carrier under the gravity of the material itself, Through the negative pressure air mixture of materials and air, into the sieve middle rotor.

Through the wind turbine blade to exert enough centrifugal force to the barrel screen spray through the net, the cyclone collector will collect the finished product together, not through the net impurities automatically discharged from the slag discharge port, so as to achieve the purpose of rapid screening.

Airflow sieve in series with high powder machine and packaging machine, not only to solve the problem of screening, but also to solve the dust of the high pressure machine positive pressure out of the dust.

|

|

BGRIMM Magnetic Materials

Magnetic material

The production process of magnetic materials is complex, and it is inevitable that there will be caking, industrial impurities and secondary pollutants entering into the raw materials, which will affect the quality. Therefore, the final screening must be carried out. Due to its high hardness, high viscosity, easy to clasp and easy to fly, it is difficult to solve the screening problem in the production process. The engineers of the north mine have also made many experiments, using vibrating screens, ultrasonic screens, or equipment using air separation and similar airflow sieves. ...

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

E-mail: gaoful@zhendongshai.com