As petroleum refining continues to expand globally, petroleum coke (petcoke)—a carbon-rich, solid byproduct—has become a widely used industrial material, especially in metallurgy, cement, and fuel sectors. However, crushing petcoke presents a unique challenge: the material is hard, abrasive, and produces significant dust when over-crushed.

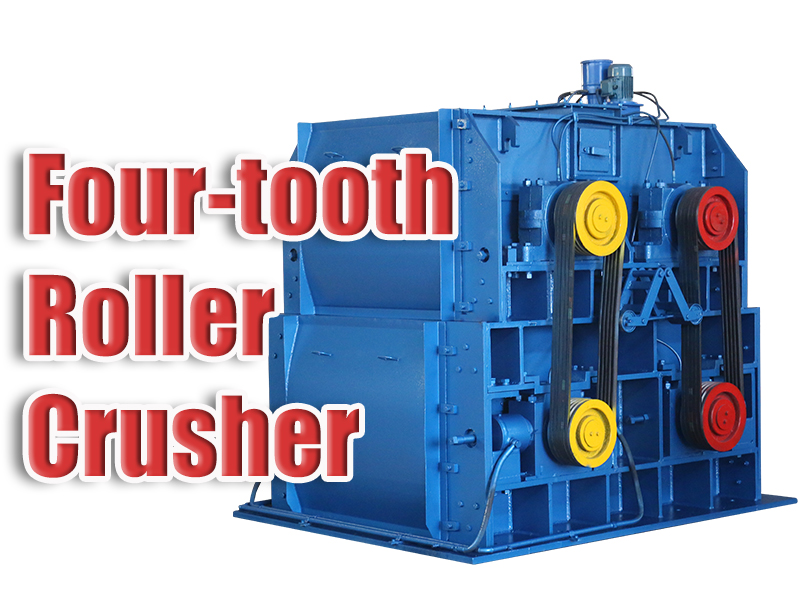

To address these challenges, the four-tooth roll crusher offers a reliable, high-performance solution designed to process petcoke efficiently and precisely. With features tailored to minimize over-crushing, ensure consistent output, and simplify operation and maintenance, it is rapidly becoming a preferred choice in modern petcoke handling and processing lines.

Engineered for Stability and Precision in Petcoke Crushing

The four-tooth roll crusher is built for intelligent, stable, and dependable operation in heavy-duty environments. Its robust design ensures that the machine can handle the abrasive and brittle nature of petcoke without clogging or sudden equipment wear. Unlike conventional crushers that rely on impact or hammer action, this crusher applies a shear-compression crushing method—a gentler, more controlled approach that delivers excellent particle uniformity without generating excessive fines or dust.

Low Over-Crushing Rate and Superior Particle Size Control

Over-crushing not only increases material waste but also creates unwanted dust that can harm equipment and reduce downstream efficiency. The four-tooth roll crusher is specifically engineered to minimize the over-crushing rate while ensuring a high-quality, uniform end product.

Thanks to the crusher's precision tooth design and uniform feed distribution, the output particle size remains highly consistent—ideal for industrial applications that demand tight size specifications. Whether you're preparing petcoke for fuel, kiln feed, or metallurgical blending, this crusher delivers precise, adjustable particle sizing every time.

Uniform Feeding for Long-Lasting Performance

Uneven feed distribution can lead to rapid wear and unbalanced crushing forces. To prevent this, the four-tooth roll crusher is designed with a uniform feeding system that ensures consistent material input across the roller width. This balanced feeding significantly reduces localized wear, extending the service life of the teeth, rollers, and drive components.

In high-volume operations, where uptime and reliability are critical, this feature translates into lower maintenance frequency and reduced operational costs over time.

Simple Structure, Easy Maintenance, Fast Adjustment

One of the standout advantages of the four-tooth roll crusher is its simple yet efficient mechanical structure. Fewer moving parts mean fewer maintenance issues and easier inspection and repair routines. Operators can quickly access internal components without complex disassembly, reducing downtime.

Even more valuable is the convenient discharge size adjustment system, which allows for fast control of product size. Depending on the model, operators can choose between a manual handwheel mechanism or a hydraulic adjustment system to fine-tune the roller spacing. This feature ensures that the machine can be adapted on the fly to meet changing material or production requirements—without sacrificing precision or safety.

Key Advantages for Petcoke Processing

- Low Over-Crushing Rate: Controlled crushing ensures minimal dust and material loss.

- Stable and Intelligent Operation: Built for consistent performance even under tough conditions.

- Uniform Feed, Uniform Output: Prevents roller wear and enhances product consistency.

- Long Service Life: Balanced design and durable materials reduce wear and downtime.

- Fast Discharge Adjustment: Manual or hydraulic systems allow precise, real-time control.

- Simple Structure, Easy Maintenance: Streamlined design saves time and reduces service costs.