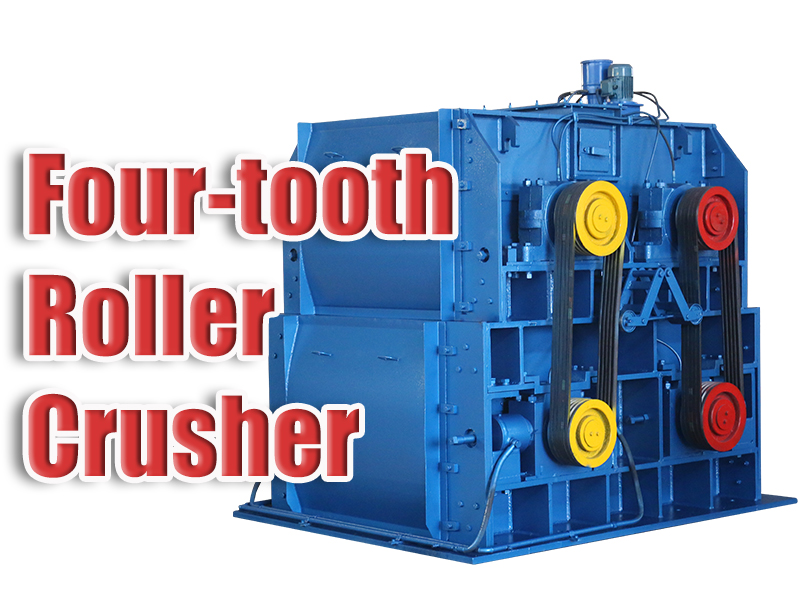

In modern coal processing, especially when handling soft, high-moisture materials like lignite (brown coal), the demands on crushing equipment are higher than ever. Lignite’s sticky texture, high water content, and tendency to clog traditional crushers pose unique challenges that require innovative design solutions. The GF series four-tooth roll crusher rises to this challenge with a combination of advanced engineering, intelligent hydraulic systems, and thoughtful structural design. It delivers not only effective crushing but also enhanced operational stability and productivity.

Tailored for Lignite: Large Teeth, Dense Configuration

One of the key features of the GF four-tooth roll crusher is its large tooth profile and dense tooth arrangement, specifically engineered to handle the fibrous, wet characteristics of lignite. These robust teeth ensure aggressive material engagement, efficiently breaking down chunks of lignite into uniformly sized particles while minimizing material build-up on the crushing surfaces.

The tight tooth spacing allows for more contact points per rotation, promoting smoother crushing action and reducing the chance of material slippage, which is particularly common when processing soft coals.

“Rapid Parallel Retreat” Hydraulic System: Intelligent Anti-Clogging Protection

A standout innovation in the GF model is its "rapid parallel retreat" hydraulic system. This feature allows the crushing rolls to quickly retract in parallel when encountering uncrushable material or sudden pressure spikes—effectively preventing equipment damage and material jamming. After the obstruction clears, the system restores the rolls to their original position automatically, ensuring seamless operation with minimal downtime.

This intelligent hydraulic mechanism not only improves equipment safety but also enhances operational continuity, especially in demanding applications like lignite crushing where sticky materials frequently threaten to clog conventional systems.

Uniform Vibration-Assisted Feeding: Preventing Material Blockage

To ensure smooth and even material distribution across the crusher rolls, the GF crusher incorporates a vibration-assisted feeding mechanism. This system ensures uniform material layering, reducing the chances of overload or blockage while maintaining a steady feed rate.

This controlled feeding plays a crucial role in achieving consistent particle size and avoiding pressure surges, which are common causes of mechanical stress and system shutdown in less advanced machines.

Unique Single-Side Motor Placement: Compact and Balanced Design

The crusher’s unique motor layout, with both drive motors placed on the same side, offers a compact and symmetrically balanced structure. This design reduces transmission losses, simplifies maintenance, and contributes to more efficient space usage in coal preparation plants. The single-side configuration also improves equipment accessibility, allowing easier inspections and quicker service times.

Key Advantages of the GF Four-Tooth Roll Crusher

- Low Over-Crushing Rate, Optimal Particle Size

The GF crusher excels at delivering well-graded crushed material with minimal fine generation. This is crucial for maintaining energy efficiency and reducing unnecessary dust and material loss during downstream processes like drying or combustion. - High Stability, Continuous High Output

Built for heavy-duty applications, the machine maintains stable operation under high loads, ensuring reliable throughput even during extended shifts. The combination of dense tooth design and intelligent hydraulic systems allows it to perform consistently without clogging, making it ideal for high-capacity production environments. - Anti-Clogging Design for Moist, Sticky Materials

Lignite’s moisture and stickiness are no match for the GF crusher’s design. Its rapid retreat system, vibration-assisted feeding, and optimized tooth arrangement all work together to eliminate the common issue of material build-up and blockage. - Low Maintenance and Longer Service Life

With fewer wear points and smart protective features, the GF four-tooth roll crusher offers extended service intervals and reduced maintenance costs. Its hydraulic retreat system also protects core components from overload-related damage.