Tumbler vibrating screen with excellent screening and impurity removal effect.

Post Date: 2025-03-21

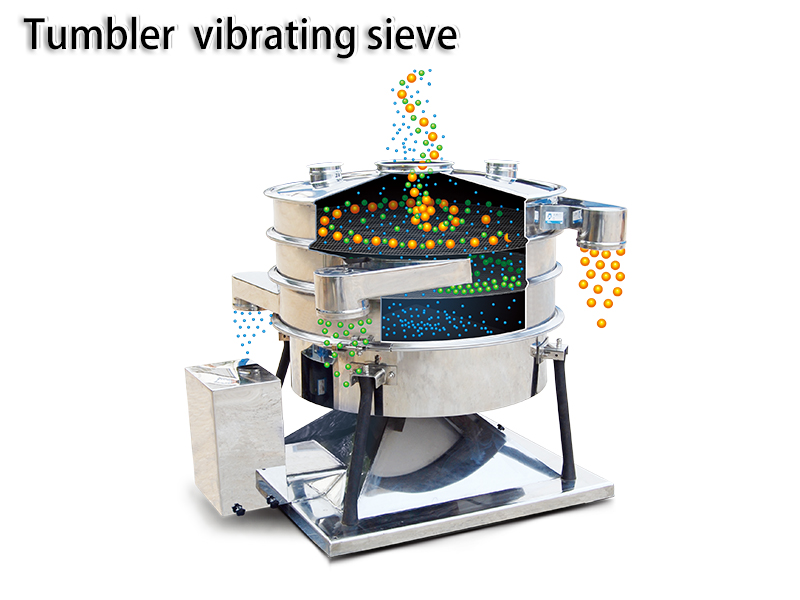

In industrial screening, achieving high efficiency and precision while maintaining a gentle handling process is essential, especially for fragile or easily clogged materials. The Tumbler Vibrating Screen is designed to meet these demands, using a low-frequency, smooth screening motion that mimics manual sieving. This innovative screening method ensures precise separation, minimal material degradation, and improved overall efficiency.

Unique Screening Mechanism: Non-Linear 3D Motion for Superior Separation

The Tumbler Vibrating Screen operates on a unique spiral motion principle, combining radial displacement with circular movement around the displacement axis. This complex non-linear three-dimensional motion is generated by an eccentric adjustable exciter, allowing the material to follow a movement pattern similar to hand-operated sieving. As a result, materials are separated with exceptional accuracy and efficiency while preventing clogging and reducing particle breakage.

Key Advantages of the Tumbler Vibrating Screen:

- Gentle, Low-Frequency Screening – Protects fragile materials from damage while ensuring precise classification.

- Three-Dimensional Spiral Motion – Creates an optimal screening trajectory that enhances efficiency.

- Adjustable Eccentric Exciter – Customizes motion characteristics for different material types and screening needs.

- Reduces Mesh Clogging – Ideal for materials prone to blocking, ensuring continuous operation.

- Compatible with Screening Accessories – Can be combined with additional screening tools to achieve even better results.

Ideal for Screening a Wide Range of Materials

The Tumbler Vibrating Screen is particularly well-suited for circular, cylindrical, flaky, and geometrically regular materials that are prone to mesh blockage. It is commonly used in industries that require high-precision separation and efficient processing of complex materials.

Common Applications:

1. Food and Pharmaceutical Industry

- Granulated sugar, coffee powder, and salt – Ensures uniform particle size distribution.

- Pharmaceutical tablets and capsules – Maintains integrity while ensuring precise classification.

- Tea leaves and herbs – Gently screens delicate materials without crushing.

2. Chemical and Plastic Industry

- Resins and polymer granules – Prevents contamination and ensures uniform granule size.

- Plastic pellets and additives – Improves product consistency in manufacturing processes.

3. Metallurgy and Powder Processing

- Metal powders (aluminum, iron, titanium, etc.) – Achieves high-precision screening for use in 3D printing and advanced metallurgy.

- Graphite, mica, and silica powders – Ensures fine classification while preventing mesh clogging.

Maximizing Efficiency with Advanced Screening Technology

The Tumbler Vibrating Screen is an essential solution for industries requiring gentle yet efficient material separation. Its low-frequency, non-linear motion effectively prevents clogging, enhances screening accuracy, and ensures the integrity of delicate materials. When combined with customizable screening accessories, it delivers even better performance and higher screening precision.

For businesses that require high-efficiency, precision screening of challenging materials, the Tumbler Vibrating Screen is the ultimate choice, offering unmatched reliability, durability, and versatility in industrial material classification.