|

Special For Medicine

|

Higher Screening Precision

|

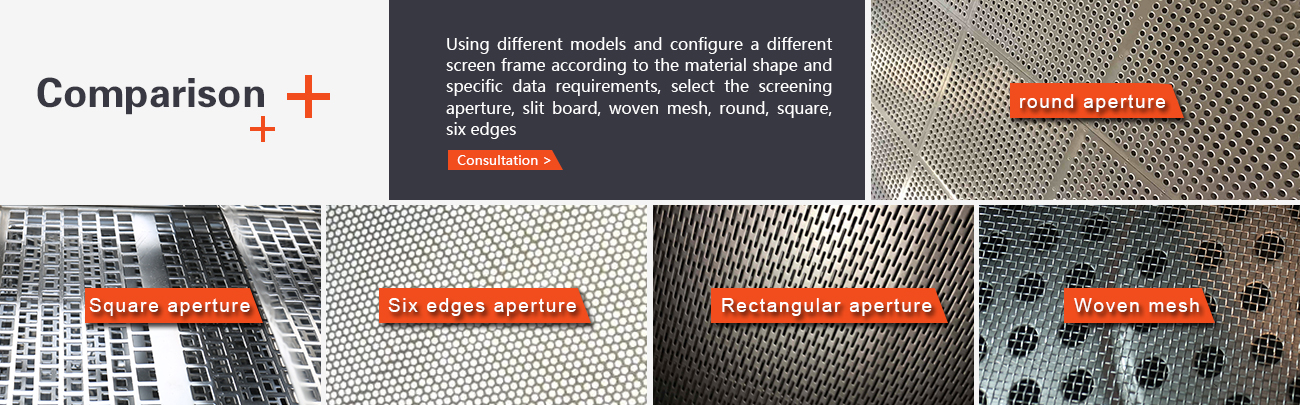

Custom Special Screen Mesh

|

||

| It is efficient to remove the large slag and fine powder from particles such as dropping pills, honey pills, granule and filling capsules. | Cooperating with feeder, the material evenly enter into the screening machine to make the material screening precision higher. | According to the particularity of each material, to develop special screen to avoid clog, increase screening output. | ||

|

Unique Design

|

Suitable For Assembly Line Production

|

|||

| Unique design for amplitude and frequency, to ensure the dry pellets without broken, wet pellet without deform, and granule powder can be divided more thoroughly. | Low energy consumption, high output, easy operation, easy to clean, fully enclosed structure, automatic discharging, suitable for assembly line production. |

| Comparison Item | Granular Square Sieve | Drum sieve |

| Effect for granule shape | Granular square sieve adopt unique structural design, the engineer designs the vibration frequency and amplitude according to the granule’s moisture, the mass density and so on, to make particles one-time through the screen mesh without other auxiliary help, so, there is no damage on the surface of a particle shape. | The principle of the drum sieve is that the medicine particles rotate along the tube wall and, which will cause damage to the appearance of the pills in the operation.Also the workings type of a drum sieve is easy to cause particle plugging, scraper or brush can be used to clean when the sieve pore jams, it's cause the secondary damage and pollution to particles, especially wet pill is particularly serious. |

| Comparison for precision ratio of finished products | Granular square sieve can customize the screen mesh with different shape , material and process, according to the required size and specification, combined with the particle characteristics; we will design the sieve flow and speed according to the site production needs, it bring about the customize design, and achieved high screening accuracy, big capacity. | The motor rotation of drum sieve through a belt drive the spindle at work, this working way can't control the direction and speed of the material, When the drum rotate quickly, the larger particles bound up with small particles rotating scroll to discharging mouth, it is easy to cause uneven classification, it will need artificial secondary selection again. |

| Comparison for clean and maintenance | Granular square sieve is the separation device, mould clamping, the s-type assembly, no dead angle, no string and no leaking, disassemble and installation fast, the parts are easy to clean. | The drum sieve is a one-piece design, the barrel body is not separated from the outside body, the dead angle is much, not easy to disassemble, cannot be branch cleaned, which can easily lead to the material residue, the sanitation inspection is not up to standard. |

Granular square sieve is Gaofu company’s empirical wisdom crystallization which engaged in medical screening equipment design and manufacturing, the machine body produce approximate circular motion driven by the motor shaft rotation traction, granule pill material rolling on the sieve surface, the size smaller than the mesh will pass, bigger than the mesh directly discharged. the whole process of material force balanced and smooth rolling, almost no damage, even wet sieving pill can also play the same effect.

| Model | Dimensions(mm) | Material Size(mm) | Angle(°) | Amplitude(mm) | Layer(s) | Power(kw) |

| GFZX-515 | 500×1500 | 0.25~15 | 0°~7° | 1~8 | 1~3 | 2x(0.15~0.25) |

| GFZX-520 | 500×2000 | 2x(0.15~0.25) | ||||

| GFZX-615 | 600×1500 | 2x(0.15~0.25) | ||||

| GFZX-620 | 600×2000 | 2x(0.25~0.4) | ||||

| GFZX-820 | 800×2000 | 2x(0.4~1.1) | ||||

| GFZX-825 | 800×2500 | 2x(0.75~1.1) |

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

E-mail: gaoful@zhendongshai.com